Table of Contents

- Understanding Tamper-Resistant Fasteners

- Applications Across Industries

- Market Growth and Trends

- Innovations in Tamper-Resistant Technology

- Challenges and Considerations

- Conclusion

As the importance of security grows across industries worldwide, tamper-resistant fasteners have become a crucial component in safeguarding assets, preventing unauthorized access, and ensuring the integrity of critical infrastructure. Unlike standard screws and bolts, these fasteners feature unique designs that make removal difficult without specialized tools, forming the front lines of modern physical security. For anyone seeking reliable solutions to enhance the durability and safety of their equipment, exploring the offerings from the best security screws provides access to industry-leading products designed for maximum protection.

Whether in public works, transportation, or advanced manufacturing, tamper-resistant fasteners offer a first line of defense against tampering, vandalism, and theft. Their unique drive patterns and materials not only discourage opportunistic attempts but also implement an effective barrier that requires intent, know-how, and specific tools to bypass. This growing reliance on specialty fasteners is not only a testament to the heightened need for security but also to the innovation driving modern engineering solutions.

Given the increasing sophistication of security threats, organizations are adopting multiple strategies to enhance their defense systems. Part of this holistic approach includes integrating robust tamper-proof fasteners alongside alarm systems, surveillance, and digital asset protections, all of which collectively form resilient layers of security. As a result, decision-makers in sectors ranging from infrastructure to defense prioritize fasteners just as seriously as other security elements.

Organizations concerned with new regulations and compliance standards, particularly in fields such as transportation and municipal safety, are seeking authoritative guidance on best practices for deploying tamper-resistant fasteners. Mainstream publications, including Forbes’ coverage of physical security, support the case for implementing these solutions as part of a greater strategic vision.

Understanding Tamper-Resistant Fasteners

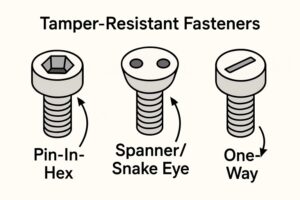

Tamper-resistant fasteners, also known as security fasteners, are engineered with drive designs that aren’t easily compatible with standard tools. This intentional complexity helps deter theft, vandalism, and unauthorized interference. The most common tamper-resistant fastener types include:

- Pin-in-Hex Screws: Enhanced with a small pin in the screw head, requiring a matching tool with a corresponding hole.

- Spanner (Snake Eye) Screws: Identifiable by two round holes in the head, demanding a specialized spanner driver for handling.

- One-Way Screws: Designed to be driven in with a standard tool, but almost impossible to remove without specialized equipment.

These unique configurations make it exceptionally difficult for unauthorized personnel to disassemble protected devices, significantly improving physical security measures.

Applications Across Industries

Aerospace and Defense

Securing mission-critical systems is a primary concern in the aerospace and defense industries. By employing tamper-resistant fasteners, organizations ensure that only properly credentialed individuals can access essential components. This practice reinforces federal safety and security protocols, minimizing the risk of sabotage or tampering in high-stakes environments. Components such as avionics panels and weapon system housings routinely utilize these specialized fasteners.

Public Infrastructure

Municipalities and utilities are using tamper-resistant fasteners to prevent theft and vandalism of public assets. Items like street signs, playground equipment, park benches, and utility access covers are frequent targets for malicious removal. By using security fasteners, cities reduce maintenance expenses and keep essential assets in place. For example, traffic light enclosures, often equipped with tamper-resistant screws, have seen a notable decline in unauthorized openings and tampering, as reported by municipal safety departments.

Automotive Industry

The surge in theft of high-value components such as catalytic converters has prompted automotive manufacturers and service providers to invest heavily in tamper-proof solutions. Fasteners now secure not only catalytic converters but also airbag modules, electronic control units, and wheel locks. These advancements are crucial for complying with regulations designed to protect consumers and mitigate financial losses resulting from theft and subsequent vehicle damage. The trend has also led to an increase in collaboration with insurance providers and law enforcement agencies to implement recognized best practices for vehicle protection, as detailed in resources such as The New York Times’ guide on catalytic converter theft prevention.

Market Growth and Trends

The shift toward advanced security requirements is fueling substantial growth in the tamper-resistant fasteners market. Industry projections estimate a robust compound annual growth rate (CAGR) of 6.3% through 2035, as security needs expand across the transportation, defense, and infrastructure sectors. Increased investment in innovative city technologies, strengthened critical infrastructure, and growing regulatory oversight are primary drivers of demand.

Innovations in Tamper-Resistant Technology

Material and design breakthroughs are shaping the next generation of tamper-resistant fasteners:

- Innovative Fasteners: These advanced products embed sensors within the fastener structure to monitor and alert when tampering is detected, expanding the functional scope of security solutions.

- Advanced Materials: The introduction of reinforced alloys and composite materials increases resistance to cutting, drilling, and other forms of damage.

- Self-Healing Coatings: These innovative coatings reveal evidence of tampering and can even restore minor surface damage, facilitating maintenance and investigation efforts.

As digital transformation intersects with infrastructure, such innovations highlight the convergence of mechanical security and intelligent monitoring, setting new benchmarks for safety.

Challenges and Considerations

Despite substantial benefits, tamper-resistant fasteners present unique challenges, such as the need for specialized installation and removal tools. This requirement may complicate routine maintenance and increase costs, especially in aging infrastructure or resource-constrained environments. Furthermore, as tamper-resistance technology progresses, so do the techniques employed by those aiming to circumvent protections, necessitating dynamic and ongoing improvements to stay ahead of emerging threats.

Conclusion

Tamper-resistant fasteners represent a vital evolution in the field of security, providing adequate protection for assets and infrastructure across various industries. Their adoption is expected to expand even further as risks multiply and new technologies emerge to counter them. Forward-thinking organizations should continue to monitor advancements and refine their strategies, ensuring that physical security remains as dynamic as the threats it faces.